How Can Circulating Conveyors Improve Your Production Efficiency?

2026-01-05

In modern manufacturing and logistics, Circulating Conveyors have become a vital part of streamlining operations and increasing productivity. Companies face increasing demands for faster delivery, consistent quality, and cost reduction, making efficient material handling systems essential. Shanghai Shukai New Equipment Co., Ltd. specializes in designing and supplying high-quality circulating conveyor solutions that address these challenges.

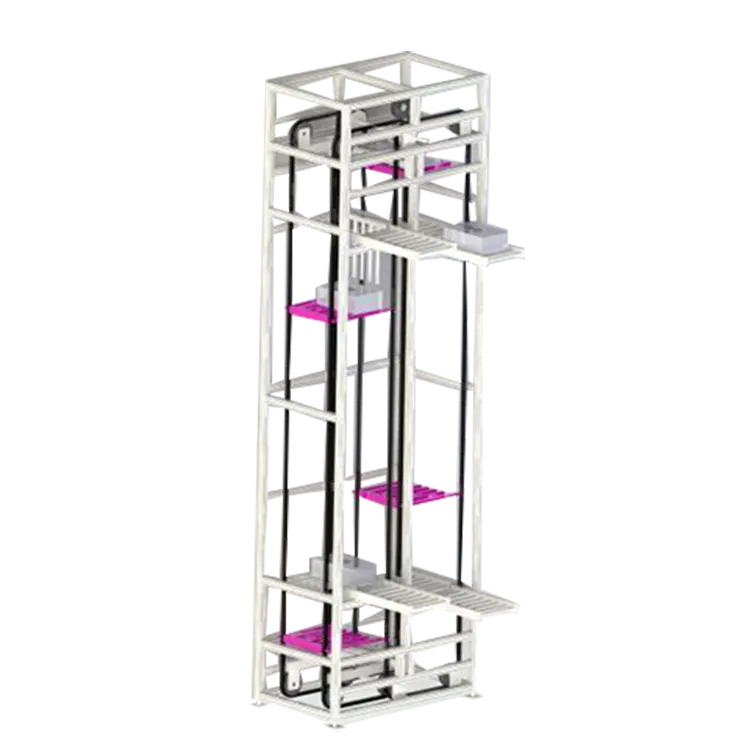

Circulating conveyors are designed to continuously move products along a loop or closed path, enabling flexible layouts and seamless integration with other machinery. Unlike traditional straight conveyors, circulating conveyors can reduce manual handling, optimize space, and improve workflow efficiency.

What Are the Key Features of Circulating Conveyors?

Circulating conveyors offer several advantages that make them suitable for a wide range of industries:

-

Continuous operation: Products move in a closed loop without stopping, ensuring smooth and uninterrupted flow.

-

Space-saving design: Ideal for facilities with limited floor space.

-

Versatility: Suitable for different types of items, from packaged goods to large components.

-

Integration capability: Can be combined with automated storage, sorting, or packing systems.

Comparison Table: Circulating Conveyors vs. Traditional Conveyors

| Feature | Circulating Conveyors | Traditional Conveyors |

|---|---|---|

| Operation | Continuous, looped | Linear, may require manual transfer |

| Space Efficiency | High | Moderate |

| Flexibility | Can handle various layouts | Limited to straight paths |

| Automation Integration | Easy | Moderate |

| Maintenance | Moderate | Low to moderate |

Why Are Circulating Conveyors Important in Manufacturing?

The role of circulating conveyors extends beyond simply moving products. They improve operational efficiency, reduce labor costs, and minimize human error. For industries such as food processing, pharmaceuticals, and electronics, these conveyors ensure a hygienic, organized, and safe production line.

By implementing circulating conveyors, companies can achieve:

-

Higher throughput: Continuous flow reduces bottlenecks.

-

Enhanced flexibility: Easily adapts to production changes or expansion.

-

Lower labor costs: Reduces manual transport and handling.

-

Consistent product quality: Reduces damage and misplacement during transport.

How to Choose the Best Circulating Conveyor for Your Facility?

Selecting the right circulating conveyor depends on production requirements, product size, and layout constraints. Shanghai Shukai New Equipment Co., Ltd. provides tailored solutions, including:

-

Overhead circulating conveyors: Ideal for assembly lines and lightweight items.

-

Floor-level circulating conveyors: Suitable for heavy loads or pallets.

-

Modular systems: Allow quick adjustments and expansion.

Checklist for Choosing Circulating Conveyors:

-

Determine product weight and dimensions

-

Assess available space and layout

-

Consider integration with existing machinery

-

Evaluate maintenance and operational costs

-

Check for supplier support and customization options

Which Industries Benefit the Most from Circulating Conveyors?

Circulating conveyors are versatile and can be applied across multiple sectors:

-

Food & Beverage: Streamlines packaging and reduces contamination risk.

-

Pharmaceuticals: Ensures precise and safe transport of sensitive products.

-

Electronics & Appliances: Handles delicate components efficiently.

-

Automotive: Moves parts and assemblies along complex production lines.

What Results Can You Expect After Installation?

Companies that implement circulating conveyors typically see measurable benefits, including:

-

30–50% faster product handling

-

Reduced labor costs by up to 25%

-

Minimized product damage

-

Optimized factory layout and workflow

With professional design and installation services from Shanghai Shukai New Equipment Co., Ltd., businesses can achieve significant productivity improvements while maintaining safety and quality standards.

Conclusion

Circulating Conveyors are no longer optional—they are essential for efficient, modern production facilities. By reducing manual handling, optimizing space, and ensuring continuous flow, these systems help companies stay competitive in fast-paced markets. Shanghai Shukai New Equipment Co., Ltd. provides expert guidance, high-quality equipment, and tailored solutions to meet your unique needs.

For more information or a customized solution, contact us today and take the first step toward transforming your production efficiency.